Navigate Tough Terrain: Why Choosing the Right Undercarriage Parts Matters

Navigate Tough Terrain: Why Choosing the Right Undercarriage Parts Matters

Blog Article

Discover Undercarriage Parts for Heavy Machinery

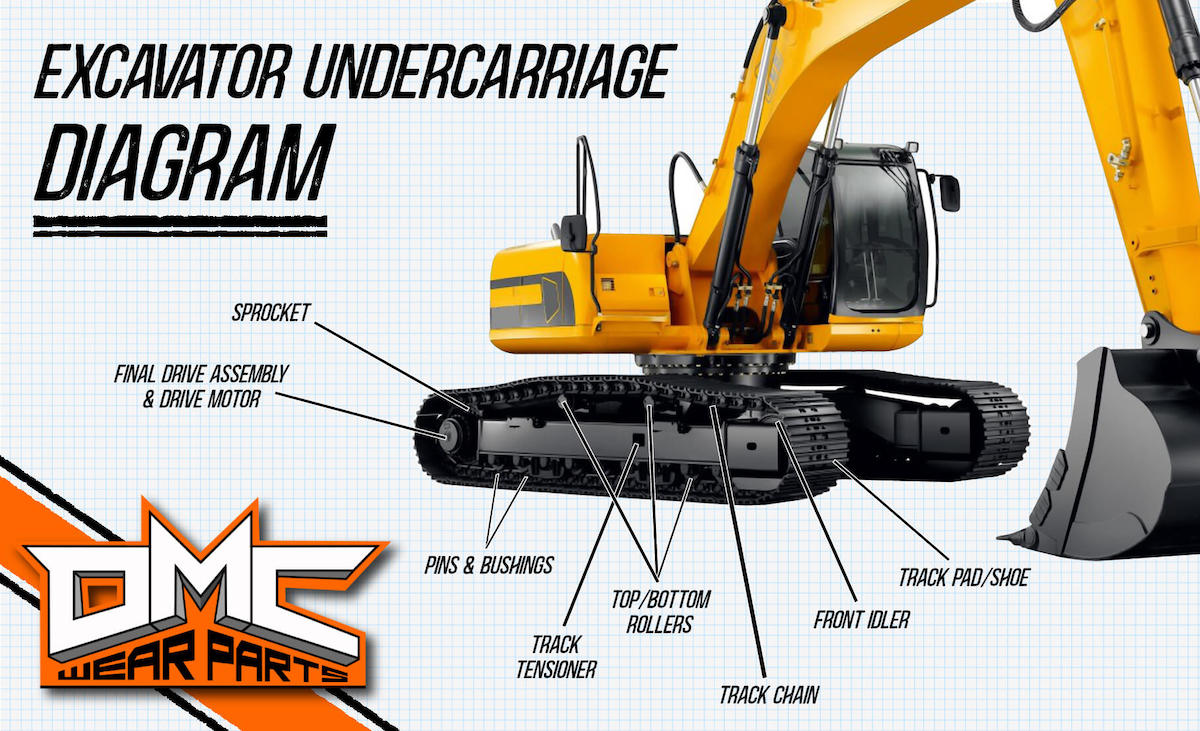

Recognizing the complexities of undercarriage components is vital for the ideal performance and longevity of hefty equipment. From track footwear to sprockets, rollers, and idlers, each element plays an important duty in the functionality of the equipment.

Relevance of Undercarriage Parts

The undercarriage parts of hefty machinery play a crucial duty in making sure the overall performance and durability of the equipment. These parts, consisting of tracks, rollers, idlers, chains, and sprockets, create the foundation upon which the maker runs. A well-maintained undercarriage not just gives stability and support to the heavy machinery but additionally contributes substantially to its functional effectiveness and performance.

Among the vital benefits of investing in high-quality undercarriage parts is the reduction of downtime and maintenance expenses. By utilizing sturdy parts that can withstand the rigors of durable applications, drivers can decrease the need for frequent repair work and replacements, thus making the most of the equipment's uptime and general lifespan.

Furthermore, appropriately working undercarriage parts make certain optimal weight traction, ability to move, and distribution, allowing the hefty equipment to run smoothly even in challenging surfaces. This dependability is essential for industries such as mining, construction, and farming, where equipment efficiency straight affects project timelines and productivity. Finally, the importance of undercarriage components can not be overstated in maintaining the effectiveness and longevity of hefty machinery.

Sorts Of Track Shoes

When thinking about the various sorts of track footwear for hefty machinery, it is important to review their layout and performance in relation to certain operational needs. Track footwear are crucial parts of the undercarriage system, providing weight, traction, and security circulation for hefty equipment such as excavators, bulldozers, and spider cranes.

One of the most usual types of track footwear include:

** Grouser Shoes **: Including elevated steel bars (grousers) along the shoe's surface, these track shoes provide improved grip in challenging terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Dual Grouser Shoes **: Similar to grouser shoes however with an extra set of grousers, these track footwear offer also better grip and stability, making them excellent for extremely harsh surfaces.

** Three-way Grouser Shoes **: With 3 collections of grousers, these track shoes offer maximum traction and stability, making them ideal for the most requiring conditions.

Choosing the right sort of track shoe is important for optimizing the performance and long life of heavy equipment while making certain safety and security and performance during operations.

Function of Rollers and Idlers

Rollers and idlers play indispensable roles in sustaining and leading the track shoes of heavy equipment during operation. By protecting against excessive slack or rigidity in the tracks, idlers contribute to the general security and efficiency of the equipment.

Additionally, idlers and rollers function together to maintain the track shoes in positioning, preventing them from sliding or derailing off during procedure. Properly working idlers and rollers are essential for guaranteeing the long life of the undercarriage system and maximizing the device's effectiveness. Routine upkeep and examination of these components are crucial to determine any indications of wear or damages beforehand, preventing expensive fixings and downtime in the future.

Role of Sprockets in Equipment

Upkeep Tips for Undercarriage Components

Effective upkeep of undercarriage parts is crucial for making certain the durability and optimal performance of hefty equipment. Routine evaluation of undercarriage components such as track chains, rollers, idlers, sprockets, and track shoes is vital to prevent unanticipated breakdowns and pricey repair work. It is additionally essential to ensure correct track stress to avoid early wear on components.

Verdict

Finally, the undercarriage components of heavy equipment play a vital duty in ensuring the smooth performance and why not look here long life of the devices. Recognizing the importance of track footwear, sprockets, rollers, and idlers, in addition to carrying out appropriate maintenance practices, can considerably influence the total performance and performance of the equipment (undercarriage parts). Regular examination and timely substitute of worn-out elements are vital in making best use of the lifespan and efficiency of hefty machinery

Rollers and idlers play integral functions in sustaining and assisting the track shoes of hefty equipment during procedure.In hefty equipment, sprockets serve an essential function in moving power from the engine to the tracks, making it possible for the equipment to relocate effectively and efficiently. These elements are attached to the axles or final drives of the equipment and job in conjunction with the tracks to drive the devices onward or backwards. Regular inspection of undercarriage components such as track chains, rollers, idlers, gears, and track shoes is vital to avoid unanticipated break downs and pricey repair services. Comprehending the value of track shoes, sprockets, idlers, and rollers, as well as carrying out why not find out more correct upkeep methods, can greatly influence the overall performance and efficiency of the machinery.

Report this page